Radman Green Energy

Leading in providing clean energy services and the official agent of the world's leading companies in IranBlogReturn to Blog

Hot spots are areas of elevated temperature affecting only part of the solar panel. They are a result of a localized decrease in efficiency, which results in lower power output and an acceleration of the materials degradation in the affected area. Solar panels generate significant power and hot spots can occur when some of that power is dissipated in a localized area. Hot spots are rarely stable and will usually intensify until total failure of the panel performance in terms of electricity production or safety.

There are multiple causes of hot spots, and they can be functional or operational. The functional reasons can be divided into two areas:

The operational reasons for hot spots are related to the solar park design and operation, and can include:

An EPC company may want to accept shading conditions in winter to increase electricity production in summer. Panels will suffer systematic shading of the bottom row of cells every morning and evening during winter. Installing panels in landscape orientation will enable the bypass diodes to work and enable the generation of 10% electricity, even in winter.

Rooftops can present challenges. When cells are completely shaded (by design of the system), this may not be sufficient to trigger the bypass diode, resulting in increased temperature, which will degrade the panel. Partial shading due to trees or tall vegetation should be controlled.

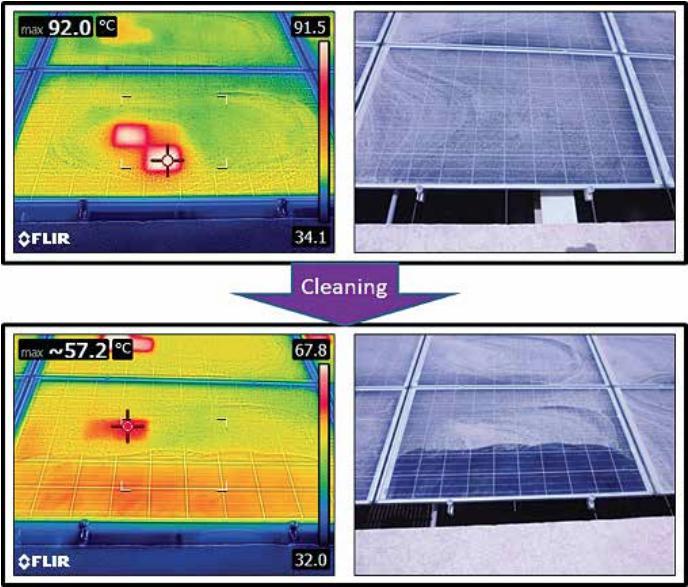

Panels can be soiled due to dust, dirt and other contaminants during their lifetime. The O&M company should also identify situations requiring cleaning, which means regular visits to the park. The frequency of cleaning will be heavily dependent on the climate conditions and ground surrounding the park.

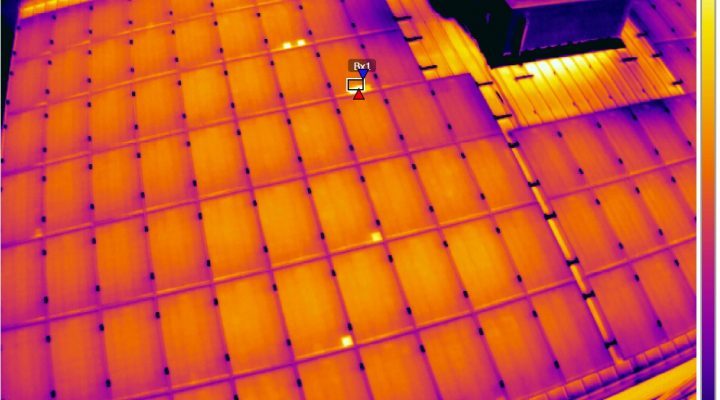

Hot spots can occur as a result of the park operation, in particular when operating in hot, dry areas prone to sanding and dusting. Underperforming cells causes hot spots. The cell will dissipate the current produced by the string and behave like a resistor, converting current into heat. The higher resulting temperature of the cell (heat) will accelerate aging mechanisms of the neighbouring materials, in particular of the encapsulant and the back sheet.

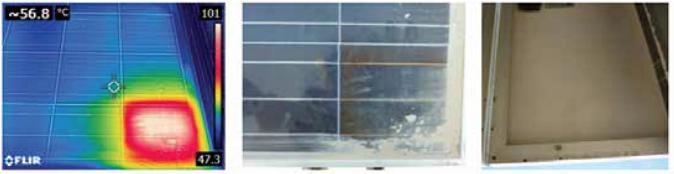

Examples of damaged back sheets due to hot spots are shown below. A tri-layer back sheet composed of PVF/polyester/PVF.

Partial shading of the cell by sand created a hot spot condition reaching 100°C (50°C above normal operating temperatures).

The consequences of hot spots can range from dramatic fires to accelerated aging of the materials and, in most cases, we will see the more diffuse temperature increase leading to an accelerated aging of the back sheet/ encapsulation material set. A hot spot resulting from, or leading to, a short circuit between the front and the back of the cell will result in very localized high intensity heating. This type of hot spot can result in melting of the back sheet and can lead to fires.

Bypass diodes are designed to cut out an underperforming string of cells to guarantee power production from the rest of the panel. An operating bypass of a string containing an underperforming cell will also prevent overheating of the cell acting as a resistor. Our experience of hot spots in the field shows us numerous examples where bypass diodes are indeed not functioning as in the field.

Radman Green Energy, the official representative of AE SOLAR Germany products in Iran, has the honour to present the AE Solar Smart Hot-Spot Free monocrystalline and polycrystalline solar modules comprise of 60 and 72 solar cells with power output ranging from 255 to 350 Watts. These modules have the ability to generate up to 30% more power depending on the albedo.

AE Smart Solar Module technology protects each cell by a Bypass diode. When the current of a single cell mismatch the current of the entire string, the bad cell will produce a reverse voltage. Then, the Bypass diode will be automatically activated if the reverse voltage is higher than 0.6V, so that the disruption will not affect the rest of the cells. Meanwhile, only the heated cell will be bypassed and the rest will continue to generate power.

The IEC61215 test indicates that hot spots will not exceed the maximum operating condition, which is 85oC. The lower temperature of these modules will eliminate potential causes for degradation of the back sheet, hence improving the reliability for longer term.

Comparing to a standard module, smart hot-spot free modules can generate up to 80% more power when multiple cells are in shade. Furthermore, the stability of PV modules will not be reduced and the risk of fire, caused by hot spot is avoided.

Watch this video for better understanding of the difference in power output between an AE Smart Hot-Spot Free Solar Module and a standard module, affected by shading cells.